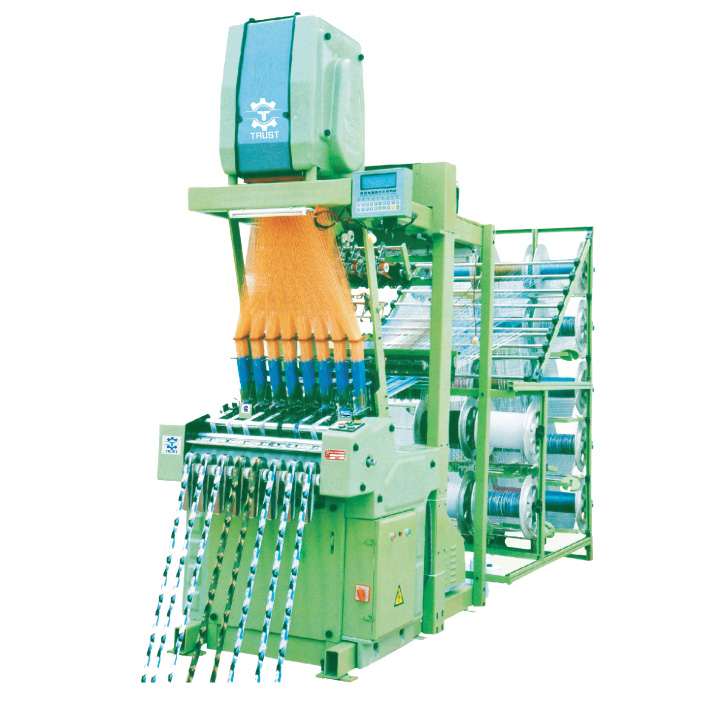

A computerized jacquard elastic machine is a specialized textile machinery used in the production of elastic fabrics with intricate patterns and designs. This machine combines the principles of traditional jacquard weaving with computerized controls to create elastic fabrics with precise and complex patterns. Here's an overview of how it works and its key features

1. Jacquard Weaving: Jacquard weaving is a technique that allows for the creation of intricate patterns and designs in textiles. It involves individual control of each warp thread, enabling the weaving of complex patterns computer jacquard elastic machine.

2. Elastic Fabric: The jacquard elastic machine is designed to produce elastic fabrics, which means that the resulting textile can stretch and recover without losing its shape. This is achieved by incorporating elastic fibers into the fabric structure computer jacquard elastic machine.

3. Computerized Control: What sets the computerized jacquard elastic machine apart from traditional jacquard looms is its computerized control system. This system allows for the programming of intricate designs and patterns, which can be highly detailed and precise computer jacquard elastic machine.

4. Pattern Input: The operator or designer inputs the desired pattern or design into the machine's computer control system. This can be done through specialized software or manually through the machine's interface computer jacquard elastic machine.

5. Warp and Weft Threads: The machine typically has multiple warp and weft threads, with the warp threads being controlled individually by the computerized system. These warp threads are responsible for creating the pattern, while the weft threads provide the elastic properties computer jacquard elastic machine.

6. Production: As the machine operates, it lifts and lowers the individual warp threads according to the programmed pattern. This allows for the creation of the intricate design on the fabric while incorporating the elastic properties computer jacquard elastic machine.

7. Fabric Take-Up: The finished elastic fabric is wound onto a roll or spool as it is produced.

Key Features of a Computerized Jacquard Elastic Machine

1. Precision: These machines can create highly detailed and precise patterns with a high level of accuracy computer jacquard elastic machine.

2. Versatility: They can produce a wide range of elastic fabrics with various patterns and designs, making them suitable for different applications like apparel, lingerie, and accessories computer jacquard elastic machine.

3. Speed: Computerized machines can operate at high speeds, increasing production efficiency computer jacquard elastic machine.

4. Automation: They reduce the need for manual control and supervision, leading to improved consistency in pattern production computer jacquard elastic machine.

5. Customization: Designers can easily change and experiment with patterns, allowing for customization and flexibility in production computer jacquard elastic machine.

6. Quality: The elastic fabrics produced by these machines are known for their quality and durability, making them suitable for various markets computer jacquard elastic machine.

7. Cost-Efficiency: While the initial investment in such machines can be substantial, they often result in cost savings in the long run due to increased efficiency and reduced labor costs computer jacquard elastic machine.

In summary, a computerized jacquard elastic machine is a specialized textile machine that combines jacquard weaving techniques with computerized controls to produce elastic fabrics with intricate patterns and designs. These machines are valuable in industries that require high-quality, customizable elastic textiles.

more information